[Home] [About] [Contact] [Writing] [Drawing] [Gifts] [Custom]

Custom: Knitting Spools

This is a project I did for a client that wanted to give some of her elderly friends a way to do some easy handicrafts. This page documents the design and devolpment work from 2012.

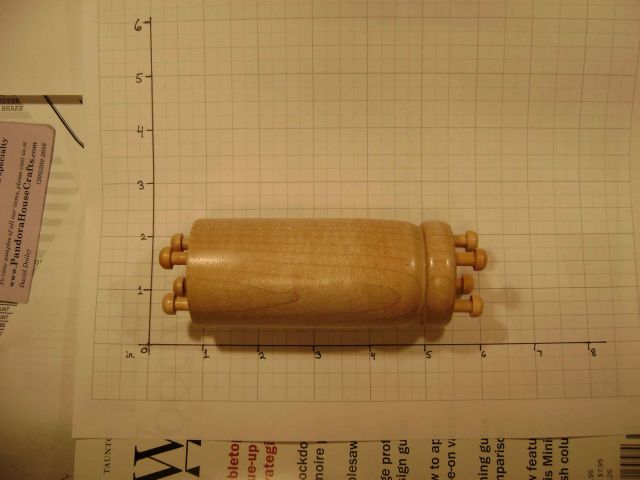

Knitting Spools: Proof-of-concept

This is the proof-of-concept model for hand knitting spools. The

example in these pictures is made of maple. The body is about

4-1/4 inches long and 1-7/8 inches in diameter. (This is

probably the most reliable diameter I can get out of two-inch-square stock, and seems plenty chunky.)

For the purposes of proving out the concept, I have made this a

double-ended model. One end has been turned to a simple

cylinder. The other end has been turned with a slight taper and a

bit of a bead. I felt that the bead would make it more

comfortable to hold.

This diameter (1-7/8 inches) feels pretty good in my hand. I

don't have to grasp tightly.

Things I would try to do differently on future models:

- Drill better center holes. In this model, the center

hole was drilled in from each end and the two holes failed to

meet up exactly. There is a shelf about 1/16 inch deep

inside the central hole and I would be concerned that it would

catch on the yarn that goes through the hole. The solution may be to acquire a longer Forstner bit, or a Forstner bit extender, or to hold the material more stably while drilling.

- Better material handling. I had a little trouble getting this model to stay put, even when held in a clamp, on my drill press table. I may need to build a small jig to assist in locating and stabilizing the spool when drilling it.

Knitting Spools: Second-Round Prototypes

The second round of knitting spool prototypes includes four

spools. All are turned to a (mostly) straight profile, and all

have similar peg configurations (4 in one end, 6 in the

other). They are turned of different woods and in slightly

different diameters.

From left to right, the woods are:

- Cuban mahogany. I have wood to make about another 4 spools. About 1-1/2 inches in diameter throughout.

- Walnut. I have wood to make about another 5 spools from this material. About 1-5/8 inches in diameter throughout.

- Mahogany (unspecified). I have plenty of wood to make several dozen spools from this material. This spool is about 1-7/8 at the 4-peg end and about 1-13/16 at the 6-peg end. The taper was not intentional, but is an example that, in general, there may be some slight taper or "barrelling" to the spool shapes.

- Maple. I have wood to make about another 4 spools form this material. About 1-15/16 throughout.

This view shows the variation in diameter a little more

clearly. The walnut and maple spools have their 6-peg ends up;

the two mahogany spools have their 4-peg ends up. Except for

the mahogany (unspecified) spool, the diameter I used was the

largest I could get from the pieces I started with.

This view shows the 4-peg and 6-peg configurations. The

smallest spool put the pegs on a slightly tighter pattern. The

three larger spools all use the same pattern. I made a jig for

marking hole locations; the jig references from the location of the 3/4-inch hole down the center.

The pegs are available only in this lighter-colored wood. They are acquired from a craft supplier and it would be way too much work to make them match the color of the spool. As before, the pegs are press-fit into their holes. Due to variations in the diameter of the peg shaft, some are tighter than others, but all are secure.

The first three photos show lots of white flecks in the spools; this is a result of the camera flash bouncing back to the lens.

This picture was taken without flash, with indirect lighting, and is a better example of what the mahogany (unspecified) spool looks

like. (However, the angle of this picture does exaggerate the

very slight taper from one end to the other in this spool.)

I recommend the mahogany for two reasons: It is easier to drill and turn, with less burning, than the maple or walnut; and I have a lot of it on hand.

I still haven't completely solved the problem of the center-hole not being smooth. Making the spool shorter is not an option because the maximum depth I can drill with the Forstner bit is about 2-3/4 inches, and that's too short for a spool. The bit extender doesn't work for this diameter of hole because it has protruding set screws. I do have another thing I can try, so we're not sunk yet.

Knitting Spools: Finished Batch of 20

And here is a finished batch of 20 knitting spools. This batch

contains two maple spools, six walnut spools, and a bunch of

mahogany spools. These are ready to be mailed to the customer,

after I wrap each one in tissue and load them into a box with

appropriate padding.

Each spool has four pegs in one end and six pegs in the other end. Pegs are press-fit. If a peg is particularly loose, it can be glued into place using either a superglue or just Elmer's glue (their wood glue would be best, but their white school glue would be fine too). If using glue, put the glue in the hole and then push the peg in-- otherwise, the glue would scrape off the peg on the way in and you won't get a good joint.